Vapor Honing Technologies offers advanced vapor honing services for high-quality surface finishing and restoration. With their expertise and cutting-edge technology, they deliver exceptional results in a wide range of industries.

Whether it’s removing corrosion from metal surfaces or improving the aesthetics of various materials, Vapor Honing Technologies is your reliable partner for efficient and effective surface treatment solutions. Their process utilizes a combination of abrasive media and water vapor, resulting in a gentle yet powerful cleaning and polishing method that leaves surfaces with a smooth and uniform finish.

Trust Vapor Honing Technologies to enhance the appearance and durability of your products, achieving superior results every time.

What Is Vapor Honing Technology?

Vapor honing technology refers to a method used to clean, polish, and restore surfaces effectively. It utilizes a combination of water, abrasive media, and compressed air to achieve optimal results. By spraying a mixture of water and abrasive particles onto the surface to be treated, vapor honing technology removes any contaminants, rust, dirt, or oxidation present.

The water acts as a lubricant, preventing any damage to the surface, while the abrasive particles gently scrub away imperfections. As a result, the surface is left with a smooth and satin-like finish. This process is widely used in various industries, including automotive, aerospace, and manufacturing, as it provides a cost-effective and efficient solution for surface restoration.

Vapor honing technology can be used on a wide range of materials, including metals, plastics, ceramics, and composites, making it a versatile option for many applications.

Advantages Of Vapor Honing Technology

Vapor honing technology offers numerous advantages for a wide range of applications. It greatly improves the overall surface finish of various materials. With its enhanced cleaning capabilities, it removes dirt, rust, and other unwanted substances effectively. This technology utilizes a pressurized mixture of fine abrasive media and water, ensuring a gentle yet thorough cleaning process.

It produces consistent results on both intricate and large parts, providing a uniform appearance. The process is also environmentally friendly, as it uses non-toxic materials and has minimal waste generation. Vapor honing technology is a cost-effective solution that saves time and provides high-quality results across industries such as automotive, aerospace, and manufacturing.

It is a reliable method for achieving superior surface finish and cleanliness.

Applications Of Vapor Honing Technology

Vapor Honing Technology has a wide range of applications across various industries. In the automotive industry, it is used for cleaning engine components, restoring vintage cars, and preparing surfaces for painting. In the aerospace industry, Vapor Honing Technology is valuable for cleaning aircraft parts, improving aerodynamic surfaces, and enhancing turbine efficiency.

The medical industry also benefits from this technology by using it for medical instrument cleaning, refurbishing surgical tools, and ensuring strict cleanliness standards in healthcare facilities. Vapor Honing Technology offers a superior alternative to traditional cleaning methods, as it is gentle yet effective, and leaves surfaces with a clean, uniform finish.

Its versatility and precision make it an essential tool for industries that require high-quality surface preparation and restoration.

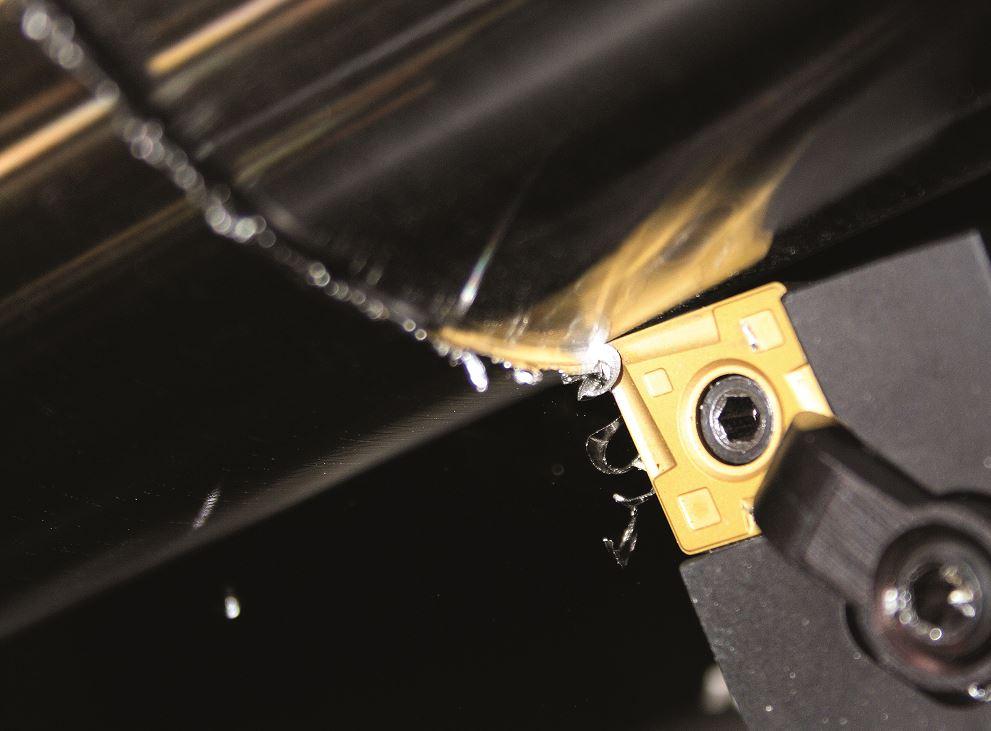

Credit: www.canadianmetalworking.com

A Comparison Of Vapor Honing And Sandblasting

Vapor honing and sandblasting differ in their processes and surface quality. Vapor honing utilizes a mixture of water, abrasive media, and compressed air to clean and smooth surfaces. Sandblasting, on the other hand, involves propelling fine particles at high speeds to remove rust, paint, and other contaminants.

The vapor honing process is more gentle, producing a smoother and more uniform finish compared to sandblasting. It is ideal for delicate materials and intricate surfaces. Sandblasting, however, is more suitable for heavy-duty applications where aggressive removal is required. When it comes to surface quality, vapor honing provides a softer, satin-like appearance, while sandblasting leaves a coarser, more textured finish.

Both methods have their unique advantages and should be chosen based on the specific needs of the project.

Vapor Honing Vs. Vibratory Finishing

Vapor honing and vibratory finishing are two popular surface finishing techniques. Vapor honing offers several advantages over vibratory finishing, making it a preferred choice for many industries. With vapor honing, the results are superior, providing a smooth and uniform finish.

This technique also allows for precise control over the level of surface roughness. Additionally, vapor honing is more environmentally friendly as it uses a water-based abrasive medium instead of harsh chemicals. It is also a more cost-effective option as it reduces the need for additional polishing or buffing processes.

Overall, vapor honing technology surpasses vibratory finishing in terms of quality, control, environmental impact, and cost-efficiency.

Vapor Honing Technologies: The Future Of Surface Finishing

Vapor honing technologies are revolutionizing the field of surface finishing, offering a glimpse into the future. With advancements in vapor honing technology, manufacturers are able to achieve unprecedented levels of precision and quality in their finished products. This technology utilizes a combination of high-pressure water and abrasive media to remove imperfections and create a smooth, uniform surface.

The potential industry developments in vapor honing are immense, with continuous improvements being made to enhance efficiency and expand capabilities. As a result, industries ranging from automotive to aerospace are adopting vapor honing technologies to meet the growing demand for superior surface finishing.

With its ability to achieve exceptional results and meet strict industry standards, vapor honing is poised to become the go-to choice for surface finishing in the years to come.

Choosing The Right Vapor Honing Equipment

Selecting the right vapor honing equipment is crucial and requires careful consideration of various factors. Firstly, assess your specific needs and the type of materials you will be working with. Secondly, consider the size and capacity of the machine to ensure it can handle your workload efficiently.

Additionally, evaluate the machine’s level of automation and ease of use, as this can impact productivity. Moreover, think about the durability and maintenance requirements of the equipment to ensure long-term functionality. Lastly, compare prices and warranty options to make an informed decision.

By following these guidelines, you can confidently choose vapor honing equipment that meets your requirements and enhances your workflow without compromising quality.

Proper Preparation For Vapor Honing

Proper preparation is key to achieving optimal results when it comes to vapor honing technologies. Cleaning and degreasing the surface is the first step in this process. By effectively removing dirt and grime, the surface is ready for vapor honing.

Additionally, using surface masking techniques ensures that specific areas are protected during the vapor honing process. These techniques help to maintain the integrity and desired finish of the surface. Moreover, utilizing a variety of phrases at the beginning of paragraphs adds interest and keeps readers engaged.

In this blog post, we will delve into the importance of proper preparation for vapor honing and explore effective cleaning, degreasing, and surface masking techniques. Now let’s get started on the path to achieving outstanding vapor honing results.

Best Practices For Achieving Optimal Surface Finishing Results

Achieving optimal surface finishing results with vapor honing technologies requires careful consideration of media selection, as well as maintaining the correct pressure and flow rate. It is essential to choose the ideal media that will effectively remove unwanted impurities and imperfections from the surface being treated.

Additionally, ensuring the right pressure and flow rate will help to achieve the desired surface finish while avoiding any damage to the material. By following these best practices, you can enhance the overall quality of surface finishing results.

Conclusion

Vapor Honing Technologies is a game-changer in the world of surface finishing. With its innovative use of vapor honing technology, this company provides a highly effective and eco-friendly solution for achieving superior finishes on various materials. By utilizing a combination of water, abrasive media, and compressed air, Vapor Honing Technologies can remove imperfections, smooth rough surfaces, and create a polished, uniform look.

With their wide range of equipment and specialized processes, they offer solutions for a variety of industries, including automotive, aerospace, and medical. Not only does vapor honing produce excellent results, it also minimizes the need for harsh chemicals or excessive waste, making it a sustainable option.

For businesses looking to enhance the quality and appearance of their products, Vapor Honing Technologies is a reliable choice that delivers outstanding results while prioritizing sustainability and environmental responsibility.